In the prior art, the cable reciprocates for a long period of time, and the sheath layer is often worn. In the electrical equipment and cable connection portion, the reciprocating motion of the outlet cable needs to be protected. The current cable is on the outside of the motor without any protection.

How to solve the technical problem of wear and break of cable reciprocating motion in the prior art?

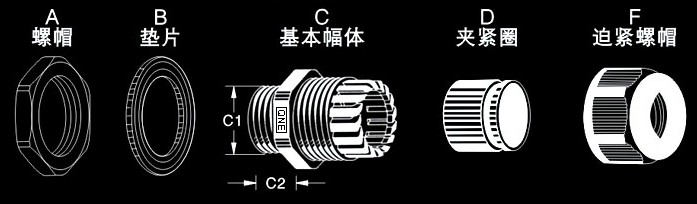

The anti-fracture cable waterproof joint recommended by us comprises a joint body, wherein the joint body is composed of a tubular member, wherein both ends of the tubular member are respectively provided with external threads, and the outer side wall of the middle portion of the tubular member is disposed An annular protruding step, one end of the tubular member is provided with a locking nut, and an elastic collar and a sealing member are sequentially disposed between the tubular member and the locking nut, and the elastic collar and the sealing member are coaxial with the tubular member. The outer outlet of the cable passing through the joint body is provided with an anti-bending spring.

Product advantages:

The anti-breaking cable waterproof joint is composed of a joint body, a spring clip, a lock nut, an anti-bending spring, a seal, an O-ring, and the joint body has external threads at both ends, when the lock nut is rotated , can force the seal to shrink, so that the cable is sealed. The shrapnel collar is connected to the cable shield to provide shielding and guiding. When the joint body is tightened, the elastic piece can be pressed, so that the elastic ring of the cable can press the shielding layer of the cable to ensure that the electromagnetic wave generated by the cable during operation is effectively grounded, and the information does not fail due to the cable shielding, and the other end of the elastic ring is By sealing with the sealing member, the sealing effect is achieved; when the metal locking cap is locked, the sealing member mounted on one side of the joint body can seal the cable; the cable is externally sheathed and placed in the anti-bending spring, and the long-term vibration of the motor causes the cable to be long-term. When reciprocating, the bending stress can be effectively absorbed, especially in the wheel motor of the new energy industry; the copper shrapnel can firmly shield the cable shield, so that the cable shield does not move, and at the same time It can effectively guide electromagnetic waves and play a grounding shielding effect; a special O-shaped groove is arranged on one end of the cable connecting device end, and the O-shaped flat integrated sealing ring which fits the same is placed in the groove, and when the product is installed, the O-ring is squeezed Pressure, into a vertical compression state, rather than radial force (easy to cause O-ring distortion, there is a failure state), to meet the sealing requirements.

If the cable needs long-term reciprocating motion to prevent the sheath layer from being worn out, the anti-breaking cable waterproof joint can be used. The circular spring is added to the brass nut to prevent the cable from being worn and broken.